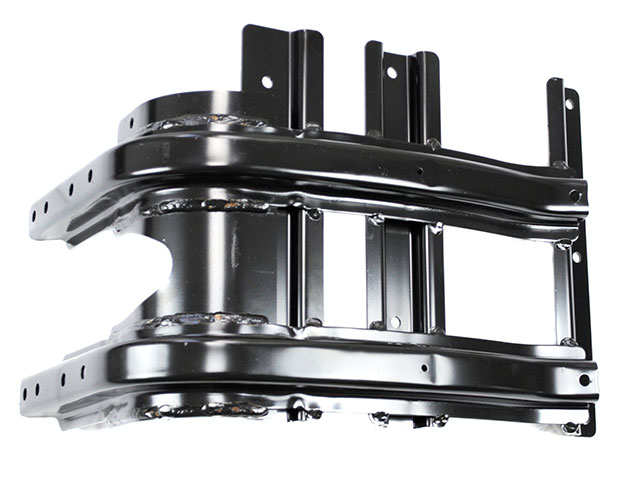

Sheet Metal Stampings

Sheet metal stamping is one of our core competencies. Sheet metal stamping is a metal forming technique through which sheet metal goes through different stages forming and cutting until an end product is reached. We have a stamping capacity ranging from 50 T to 300 T, and a wealth of experience; we are able to manufacture a wide variety of products.